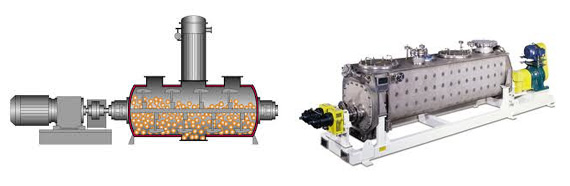

Paddle drying -

Paddle dryer is a mechanically agitated, indirect heat transfer devices that add or remove heat from a process mass. They are used for drying, heating, cooling, pasteurization, crystallizing.

Typical application areas include Salts, Catalyst, Cellulose, Starch and derivatives, Sulfates, Hydroxides in Chemical industries, PP, PET, Polycarbonate, PTA in Polymer & Plastic industries, Flour, Beverage powders, Confectionary ingredients, Meat products in Food processing…..

We offer complete instrumentation package solution including : Solid feed control : Volumetric (or) Gravimetric feed control. Feedback and Feed forward loops based on Product temperature, Hot air generator outlet temperature, paddle dryer zone temperature Dust emission control, Spray liquor/ water control. Thermic Oil Heater –Combustion control, Air/ Fuel ratio control. Oxygen trim, Supply/ Return oil heat balancing. Paddle dryer pressure control.

Cyclone, Scrubber controls including air flow control, Emission level monitoring and control. Product cooler circuit, Cooling air control, Hot air recirculation, Waste heat recovery systems. Paddle dryer zones temperature profiling and zone temperature control. Safety interlocks, Equipment protection alarms, condition monitoring of rotating equipment.