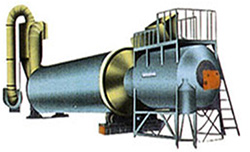

Rotary drying -

Rotary dryer/ Calciner is a type of dryer employed to minimize the liquid moisture content of the material it is handling (or) are used to cause chemical reactions or state changes in varying materials by bringing it into direct or indirect contact with a heated gas. Typical application includes Food products, Mining products, Mineral products, Fertilizer products, Chemical products, Agriculture products, Agglomeration etc…

We offer complete instrumentation package solution including : Solid feed control : Volumetric (or) Gravimetric feed control. Semisolid feed control : Feed rate control, Consistency control. Feedback and Feed forward loops based on Product temperature, Hot air generator outlet temperature. Dust emission control, Spray liquor/ water control. Product Bulk density monitoring and control.

Hot air generator – Direct/ indirect heaters, Combustion control, Air/ Fuel ratio control. Kiln back end pressure control.Cyclone, Scrubber controls including air flow control, Emission level monitoring and control.

Product cooler circuit, Cooling air control, Hot air recirculation, Waste heat recovery systems.

Kiln zones & product temperature, Skin temperature profiling. Safety interlocks, Equipment protection alarms, condition monitoring of rotating equipment